If we total those numbers, we get 180 total units sold over the past 90 days. Specializing in last-mile delivery logistics, Circuit for Teams makes sure your well-calculated inventory arrives exactly where it needs to be and when it needs to be there. Calculating reorder points is a critical part of inventory management, but it’s not the only piece of the puzzle. So, if you get your ROP right, you’re not going to run out of products.

Do it well, and this results in not just a balance in your inventory, but better management and cost reductions. Regardless of the size and scope of your business, a critical element for success is the ability to manage stock effectively. It also saves you money long-term by trimming inventory with lower sales. You should place a new order with Supplier B once your stock hits 1,451 workout shirt units. Incorrectly managing your inventory comes at a steep price and the likelihood of this happening increases as your portfolio grows. However, many retail companies don’t give their stock orders the attention needed to manage them correctly.

Rop Formula Calculator

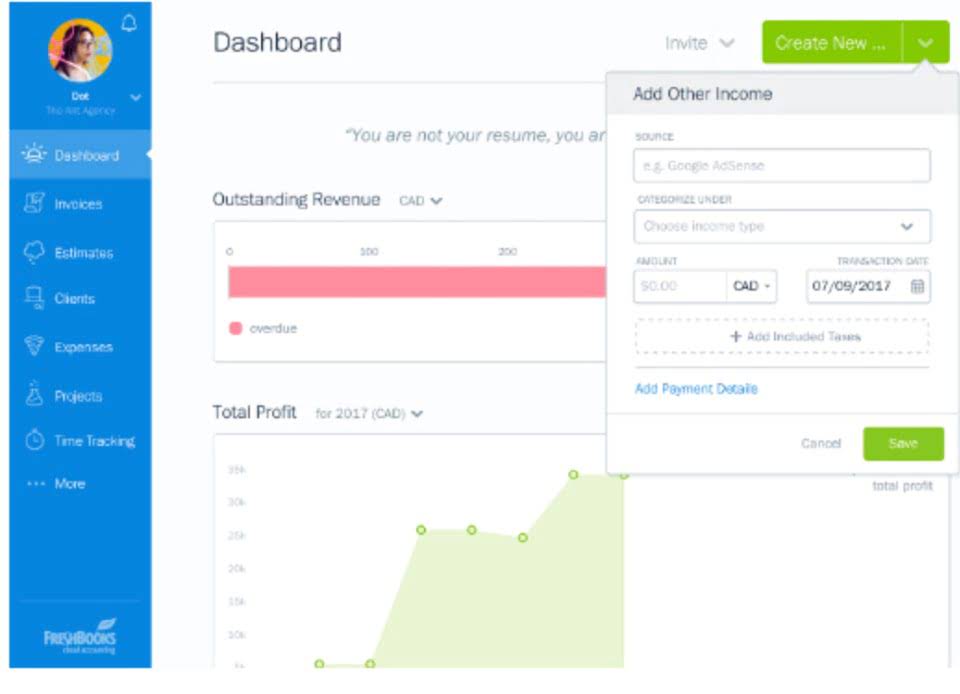

Keeping optimal stock levels in order to avoid stockouts is an integral task of inventory management. One of the most fundamental ways in which to ensure this is setting and maintaining the right reorder points. Implementing reorder points allows you to trigger a new order so you don’t get close to running out of inventory. Setting accurate reorder points allows businesses to avoid having products out of stock while waiting for new inventory. By doing this, you ensure customers get their orders on time and have a positive brand experience. The average lead time in days is how long it takes for your raw materials to be delivered from a supplier or how long it takes you to manufacture a product.

- One of the most fundamental ways in which to ensure this is setting and maintaining the right reorder points.

- The optimal reorder point will maximize the profit you can make from your stock and avoid surplus inventory in your warehouse.

- For example, if you run an online clothing store and successfully deliver 65, 70, and 45 products in the first three months of the new financial year, respectively.

- Once you manage your inventory using ROP and ensure the availability of products for your customers, you should streamline your delivery operations for complete customer satisfaction.

- If you avoid reordering products at the right time, your customers can reduce the potential revenue.

- Knowing [your] business, including target, risk, and cost, is the first and necessary step [to setting reorder points].

However, there are two ways you can prepare yourself for any issues in average lead time. That way you can still fulfill new orders and use batch picking while awaiting products in shipment. Second, calculate your reorder point daily to notice any calculate rop fluctuations in lead time demand as they occur. This way you can order products earlier if you discover any issues when inventory forecasting. Safety stock is the amount of inventory a business holds to mitigate the risk of shortages or stockouts.

Tips for setting reorder points

Your inventory reorder point levels should cover every item in stock, including all different SKUs. You can link your inventory levels with each product’s bill of materials (BOM) and track it with MRP software. More than that, you should be running the reorder point formula for each product often to ensure that your figures remain accurate. This is particularly true for businesses that are affected by seasonality, like online fashion retail.